Project Summary

Nowadays the overall energy demand in steel production is mainly based on fossil fuels, so it is fundamental to find and set new ways to overcome the environmental impact of steel production. Currently, the state-of-art of reheating furnaces is based on CH4 burners, with an evident environmental impact on CO2 emissions.

The main objective is to decarbonize this process, based on the introduction of hybrid heating technology, based on electrification and gas-burning properly combined. This solution provides an opportunity to explore the synergic effect of different technologies, by "hybrid heating".

The partial electrification of the furnaces will be realized by the installation of an induction system and an innovative conduction system. In both cases, the electricity that will use for the hybrid heating will be provided by a renewable source (RES).

Overall Concept

The concept of MODIPLANT project is to introduce in two targeted steel processes (hot dip coating of coils and hot rolling of billets) sustainable heating technologies, that are RES induction furnace for coils and RES conduction heating for billets. Both the techniques are fed by RES electrical energy, so CO2 emissions related to process are net to zero. The alternative heating systems are supported by customized research activities, addressed to improve the knowledge about metallurgical impact and with the aim to configure the operative windows, during trials.

Based on TRL on two technologies, MODIPLANT foresees to implement a commercial industrial furnace in industrial environment at Marcegaglia plant (located in Ravenna); on the other side, conduction heating based on Joule effect can be considered a break-through technology, with high potential but not ready for industrial implementation. For this reason, in the frame of MODIPLANT project, a pilot plant with conduction heating technology will be realized in Feralpi Siderurgica site.

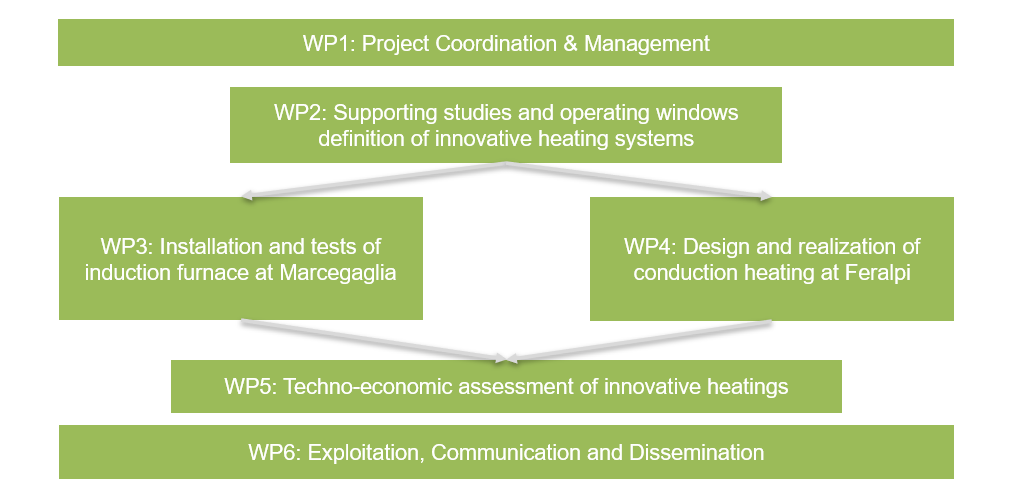

Work Plan

The project is divided into 6 WPs.

- WP1 concerns the coordination and management of the project

- WP2 is dedicated to all the studies on support on the realization of the technology in the steel plants starting from modelization of the parameters to the characterization of the steel after the process.

- WP3 reports all the activities around the design, installation and test of induction furnace, located at Marcegaglia site in Italy

- WP4 regards the actions for the realization of a full-scale plant, based on conductivity heating technology. The plant is in Feralpi Siderurgica facility, in Italy

- WP5 is focused on the impact of introducing different technologies (at low CO2 impact) on rolling mills plant.

- WP6 concerns the activities related to dissemination, exploitation, and communications.